Step‑by‑Step Guide to Sourcing Injection Molding in China

Well, the major meeting has just concluded. your new product is a go, the schedule is tight, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. It makes sense on paper. Savings can be substantial. But your mind is already racing. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

Here’s the thing, though. Sourcing China injection molding can be a calculated project. It’s no different from any structured project. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

So, what goes in it?

Start with your 3D design files. They cannot be skipped. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. Here you specify what 3D can’t show. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

Okay, your RFQ package is a work of art. now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

But don’t stop there. Perhaps hire a local sourcing specialist. True, they charge a fee. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. On your first run, this is like insurance. Consider it timeline insurance.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It blends technical checks with intuition.

Step one: audit communication. Is their turnaround swift and concise? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Then comes the audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

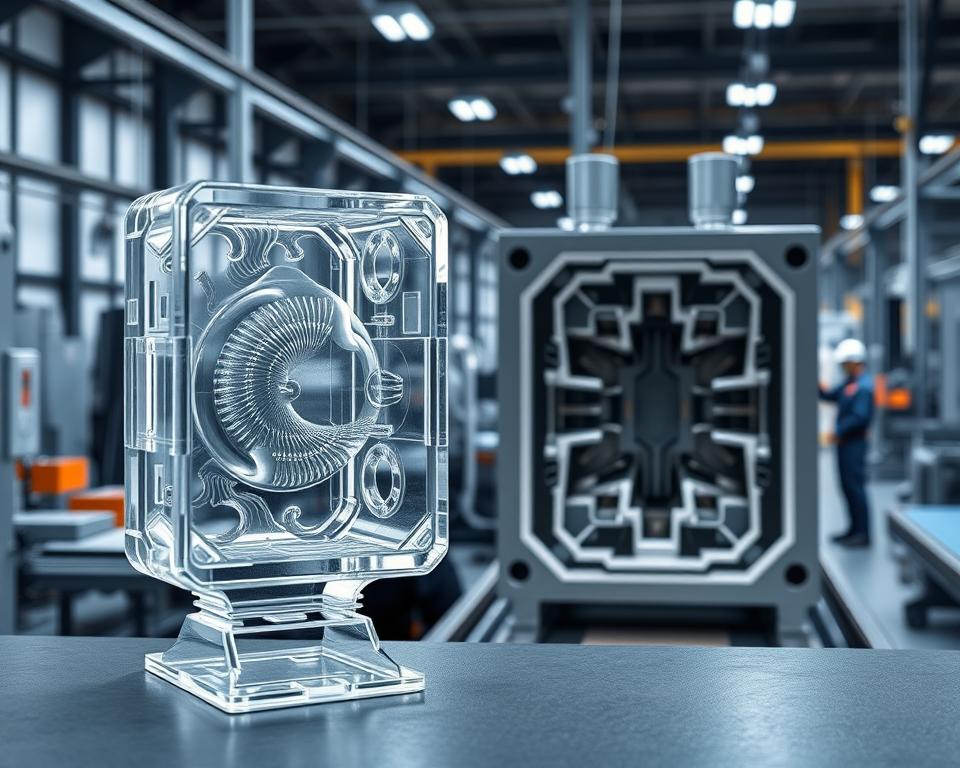

Transforming CAD into Real Parts

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

Your supplier’s first deliverable is a DFM analysis. DFM means Design for Manufacturability. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. They are your moment of truth.

T1 parts usually require adjustments. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. It could require several iterations. Build buffer time for sample iterations.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You sign off, and it serves as the master quality reference.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They provide a photo-filled inspection report. Once you sign off, you greenlight shipping and the last payment. This audit shields you from mass defects.

Finally, think about logistics. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It relies on partnership-building. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. No question, it’s demanding. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.